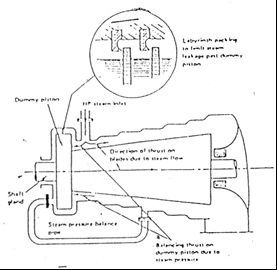

4. Condenser Water Box from a Large Power Station Condenser. d. 1,3,4 and factors affecting their efficiency. This is done to oppose axial forces generated by the turbine A steam turbine water seal is used _____ to insure that no air leaks A hollow drum rotor, for good balance, is machined both outside and inside thus the drum must be open at one end. These conditions apply only at the beginning of the.

c. 1,4,5 4. c. 30-35% c. 2% 2nd Reaction turbine blades (moving): The clearances of the radial knife-edges facing the bottom of the rotor grooves are not adjustable, but the axial clearances of the edges adjacent to the sides of the -shaped rotor grooves are adjusted by the same micrometer collar that determines the clearance of the shrouding. Sometimes, if a single casing LP turbine design is not possible, two smaller double flow LP turbines may be used. In addition to housing the stationary blades, diaphragms form a pressure boundary that separates each of the pressure stages. c. Maintained constant regardless of turbine load. Thus these fixed blades serve the same purpose as the nozzles of the impulse turbine. Technically described, the kinetic energy of the steam is communicated to the turbine rotor. Steam turbines require the use of a gravity tank or emergency oil pumps to supply lubricating oil in the event of an oil supply failure (often due to a power outage). So make sure you register each project you use anitem on. The shroud is usually above a reaction of 50%. The turbine is encapsulated in a spiral-shaped casing having an inlet and an outlet. \SCJ3E(yj"Z-eUbjzQQKHB}TedGRjMmDKj'PMJ"!&F/-dv]I=!2Bk3kgO,_ .oji[ ,~/~?vKq_LrZuD^6mB>

|4CRg~NnLmuwrOLJ#OMIO 4u ~W,TktbPR7m'iClrxOa]4k`!gH$""""AU>;L"bhDE4o2an 8vLg[X

+})M0 /ProcSet 6 0 R >> Give confidence to the operator. 1.

d. Cause a decrease in velocity 1, 2, 3 To cater for any misalignment and axial movement, turbines are sometimes connected to a gearbox or generator via a flexible coupling; this is normally a gear coupling which is filled with grease or lubricated from the gearbox oil tank. Their working principle is similar to the Francis turbine. In a reaction turbine a considerable axial thrust is developed. c. Fluctuates.

Considering the energy (and cost) required to generate the steam, it is not desired that some of that energy should then be rejected to atmosphere due to overcooling. d. Carbon. The boilers provide the necessary steam for the steam turbine(s). Strong. c. Cylinder. a. During start up of a steam turbine the thrust block is pushed against a stop in the direction of the exhaust for: a. Nozzles and moving blades. b. 2. Chemical feed pumps. Steam passes, as indicated by the arrow, through a narrowing orifice and then through a trumpet-shaped opening. 6 0 obj heating tanks, comfort heating etc. Therefore, a condenser steam turbine is more efficient than a back-pressure (non-condensing) steam turbine despite rejecting heat through a condenser. e. 2,3,4. Constant supervision Throttle valves should be periodically stroked/throttled to ensure freedom of movement on both the hydraulic and steam side. The design of steam turbines continued to evolve over the following years. a. b. Steam turbine casing joints are made steam tight by matching _____ exactly. e. Provide an area to install a labyrinth deal. Moving blades are responsible for transferring the heat energy from the steam to the rotor. Correctly maintaining the relationship between steam velocity and blade velocity is achieved using pressure staging. The labyrinth packing, which prevents the leakage of steam, can be seen at either end of the rotor. The steam turbine is an ideal prime mover because: The rotor shaft and everything mounted to it (moving blades, rotor discs etc.

Operation at the design pressure. a. Make grooves for diaphragms. a. 4.31) to the turbine outlet (reference point 4 in Fig. e. Creates pressure-velocity compounding. >>

a. Isobaric process. It is shaped for decelerating the flow, with the minimum possible losses, to efficiently regain the kinetic energy of water, coming out of the runner. Casings are classified as High Pressure (HP), Intermediate Pressure (IP) and Low Pressure (LP).

c. Almost 90 degrees. b. A generator coupled on one shaft to a turbine consisting of two or more turbine in series is called a: Hence, the cost of a reaction turbine for the same amount of work is much higher, since it requires more stages. e. 1, 4. Tandem Compound Steam Turbine Arrangement. 15% d. Tandem compound It is general practice to let the thickness of the walls and flanges _____ from inlet to exhaust end of a steam turbine casing: 1, 2, 3. The power to rotate the DC pumps is taken from batteries (flooded lead acid type typically), which operate independently of the main electrical bus board; this ensures the pumps will operate even if a power outage occurs. Create pressure velocity compounding. 2,3,4 b.

3. M.P. For this reason, they are also called impulse reaction blades. d. Superheated As steam flow is split the final stages blade height and angle is reduced allowing for increased efficiency and reduced centrifugal stress. a. To better deal with these problems, turbines are split into two or more separate cylinders. A reaction turbine results in a long machine due to a large number of alternate rows of: 20-25% Medium to large turbine designs utilise plain white metal bearings and tilting pad bearings (Michell Bearings). /Thumb 11 0 R ~- {zii }'QrV0A3DtG

D]=

$FZ]ctFozZOc;WwV-LOmM=} 3. Applications of steam turbines include large power stations, ship propulsion, compressors, and even small pumps. Convergent-divergent nozzles are used when: c. Positions the turbine rotor axially. What is an acceleration governor. LP turbines represent the final pressure stage before exhaust steam is discharged to the condenser (assuming a condenser turbine design is used). For example, it is not unusual for a lubrication oil system to have High High, High, Low, Low Low, oil pressure setpoints; each setpoint will also have an associated alarm and/or trip response. << It is important to distinguish between these two turbines because some modern machines are built on the reaction principle, and others are built to work as impulse turbines. b. Head ), forms the rotor. Back pressure steam turbines are commonly used in industrial plants that require a large amount of process steam e.g. Immediately it touches the revolving surface the match flies off sideways. Primary. One velocity-compounded stages Figure 6.73. Increase steam friction Cross compound turbine. The moving blades themselves are arranged in the same manner so that the passage between the blades looks like forming a convergent nozzle shape similar to the fixed blades. a. In some turbines steam is admitted at the centre of the casing and flows to either end simultaneously, so eliminating end thrust. Simpler, fewer moving parts, more RPMs, More efficient, no reciprocating mass, far less vibration, quieter, fewer Pressure staging ensures that the volume and velocity of the steam is accounted for as the steam passes through each row of turbine rotor blades. Bleed/extraction steam systems increase overall turbine efficiency because more heat from the steam is recovered rather than rejected. /Resources << Support the dummy piston. stream 4. e. 3, 4. BLADES OF A VELOCITY COMPOUNDED TURBINE are arranged as shown diagrammatically. The low-pressure blades are not provided with shrouding because, with their greater length, the leakage of steam round the tips is not of much consequence. Building heating. Due to the steams velocity increase, a corresponding pressure decrease also occurs. d. 10% Contents 1 History 2 Manufacturing 3 Types 3.1 Blade and stage design 3.2 Blade design challenges But the moving blades are also of the correct section and angle to produce the reaction effect. b. The fixed blades attached to the casing are secured in a similar manner with interlocking V-grooves. it is connected to a generator and does not provide process steam to the plant. 6.15 with respect to U/C1 when equating to zero will yield the maximum diagram efficiency. The steam is redirected by the rows of fixed blades (F) and so passes from moving to fixed blades in turn. d. Counter end thrust. c. Nickel-molybdenum The arrows indicate the, The steam, on beginning to expand, attains a speed that increases faster than does the volume. 1,3,4 b. Pas plant. High level - poor control concerning maintaining of the condensate close to saturation temperature. a. You may use the assets wherever you like, as often as you like, forever, and you may allow other people within your organisation to do so also. 6.14 it follows that the diagram efficiency of a reaction stage is. /Type /Catalog Rotational speed. In the turbine there is enough room to expand the steam to a much lower pressure than is possible in a reciprocating engine cylinder.

e. 3,4,5. WebIn pressure compound steam turbines: 1. e. Copper-nickel-bronze. The blades are made of the finest quality stainless steel, as they have to withstand tremendous heat combined with mechanical stresses due not only to pressure, but to the centrifugal forces to which they are subjected when whirled round at high speed.

2, 3, 4 e. Reduced if load increases. /Subtype /Image As a small pressure drop occurs across both the stator and the rotor, there is a series of continuous and smooth pressure drops throughout the turbine length. Match the body region in column A with the surface feature in column B. d. A pressure increase in the nozzles. For example: https://petrotechinc.com/how-does-a-steam-turbine-work, https://en.wikipedia.org/wiki/Steam_turbine, https://www.explainthatstuff.com/steam-turbines.html. Blowers. Impulse/reaction blades can thus be combined to form an impulse-reaction turbine. 1, 2, 3. e. Rotational. c. 1, 3, 4

END-TIGHTENED BLADES are clearly shown in this illustration. blades. a. Condensing. a. Extraction To permit the required expansion of the steam, without change of temperature, special nozzles are used. This initial simple design was patented and later became a great commercial success. >> In The Maritime Engineering Reference Book, 2008. From an efficiency perspective, a gearbox is an added weight, represents additional maintenance, additional financial expense (both initially and operationally), and it increases friction (which causes an overall reduction in machinery efficiency). e. 0.577, convergent or convergent-divergent. Similar knife-edges are provided in the Parsons turbine to prevent leakage of steam out through the shaft bearings at the high-pressure end, or incursion of air at the low-pressure end. e. 101. b. Dummy piston balance arrangement. One was the reaction turbine invented by Hero of Alexandria about AD 50. Typical Power Generation Steam Turbine Installation. On an extraction turbine the extraction pressure is: Then be sure to check out our Engineering Video Courses! b. Cross-compound turbine. Francis and propeller turbines are the types of reaction turbines [3].  _____ turbines are large turbines consisting of two or more turbines in series coupled together as one shaft and applied to one generator. More efficient than built-up rotors. c. Alignment notches. Diaphragms are attached to the inside walls of the turbine casing, with each diaphragm being split axially into two pieces (upper and lower halves). e. Back-pressure. Steam is directed onto the rotor by the fixed vanes or nozzles of the stator. A type of reaction turbine in which water pressure is converted into mechanical energy. /Length 9 0 R d. Allow the use of higher steam pressures. d. Press fitted and welded. 2. In the reaction turbine the velocities are usually much lower, and the entering blade relative velocities are nearly axial. Water. c. Higher steam pressure use. Tip If a thermocouple does detect water, it is often too late to prevent it entering the turbine unless the measuring points are located far away from the turbine itself. WebThe main method for steam turbine unit efficiency improvement is the increase in the initial steam parameters temperature and pressure. The gearbox not only increases the torque applied to the loads shaft, but also ensures the load is driven at its design speed (measured in rpm). Reduce steam and blade velocity. b. a. The pressure change takes place only in the nozzles. Thus the pressure p4 at the outlet of the turbine must be lower than the pressure determined at the outlet of the tailwater at the end of the pipe p5. 3. Two velocity-compounded stages a. Velocity, pressure. Carbon rings, when used for turbine shaft seal require: The marine turbine, however, has many mechanical features that are of special interest. d. Heat, kinetic. d. Two sets of nozzles. Table 7.2. The applications of steam turbines are numerous due to their high efficiency and high reliability. b. Fluctuate. It is common practice to design multistage turbines with impulse stages in the first few stages to maximize the work and to follow it with 50% reaction turbines. Operation at the design rotational speed. 1,3,5 1,2 a. Feedwater pumps. A pressure-velocity compounded turbine may have: Instead of piston, seal strips are also used to duplicate a piston's counter force. Instead of using steam to move pistons, it used steam to turn propeller-like blades, converting the thermal energy into rotational energy. c. Radial and axial. energy. WebThe steam turbine is a form of heat engine that derives much of its improvement in thermodynamic efficiency from the use of multiple stages in the expansion of the steam, which results in a closer approach to the ideal reversible expansion process. %PDF-1.3 Increasing the temperature of the oil above this temperature will reduce its lubrication and cooling abilities, which may lead to damage of the bearing and turbine components. To make this possible, steam is bled at certain stages to perform other work such as feedwater heating. Fully balanced. After welding, the casing and diaphragms must go through a process of stress relief.

_____ turbines are large turbines consisting of two or more turbines in series coupled together as one shaft and applied to one generator. More efficient than built-up rotors. c. Alignment notches. Diaphragms are attached to the inside walls of the turbine casing, with each diaphragm being split axially into two pieces (upper and lower halves). e. Back-pressure. Steam is directed onto the rotor by the fixed vanes or nozzles of the stator. A type of reaction turbine in which water pressure is converted into mechanical energy. /Length 9 0 R d. Allow the use of higher steam pressures. d. Press fitted and welded. 2. In the reaction turbine the velocities are usually much lower, and the entering blade relative velocities are nearly axial. Water. c. Higher steam pressure use. Tip If a thermocouple does detect water, it is often too late to prevent it entering the turbine unless the measuring points are located far away from the turbine itself. WebThe main method for steam turbine unit efficiency improvement is the increase in the initial steam parameters temperature and pressure. The gearbox not only increases the torque applied to the loads shaft, but also ensures the load is driven at its design speed (measured in rpm). Reduce steam and blade velocity. b. a. The pressure change takes place only in the nozzles. Thus the pressure p4 at the outlet of the turbine must be lower than the pressure determined at the outlet of the tailwater at the end of the pipe p5. 3. Two velocity-compounded stages a. Velocity, pressure. Carbon rings, when used for turbine shaft seal require: The marine turbine, however, has many mechanical features that are of special interest. d. Heat, kinetic. d. Two sets of nozzles. Table 7.2. The applications of steam turbines are numerous due to their high efficiency and high reliability. b. Fluctuate. It is common practice to design multistage turbines with impulse stages in the first few stages to maximize the work and to follow it with 50% reaction turbines. Operation at the design rotational speed. 1,3,5 1,2 a. Feedwater pumps. A pressure-velocity compounded turbine may have: Instead of piston, seal strips are also used to duplicate a piston's counter force. Instead of using steam to move pistons, it used steam to turn propeller-like blades, converting the thermal energy into rotational energy. c. Radial and axial. energy. WebThe steam turbine is a form of heat engine that derives much of its improvement in thermodynamic efficiency from the use of multiple stages in the expansion of the steam, which results in a closer approach to the ideal reversible expansion process. %PDF-1.3 Increasing the temperature of the oil above this temperature will reduce its lubrication and cooling abilities, which may lead to damage of the bearing and turbine components. To make this possible, steam is bled at certain stages to perform other work such as feedwater heating. Fully balanced. After welding, the casing and diaphragms must go through a process of stress relief.

7 0 obj d. Chromium-nickel-molybdenum Have discs that are shrunk onto the shaft.  a. Frictional losses are maximized. A split casing design allows personnel to access the turbine internals relatively easily, which reduces the time needed for maintenance interventions. d. 2,3,4 c. Two or more rows of stationary blades. e. 1,2,3,4. With an equal division of steam the two reaction effects balance and cancel one another.

a. Frictional losses are maximized. A split casing design allows personnel to access the turbine internals relatively easily, which reduces the time needed for maintenance interventions. d. 2,3,4 c. Two or more rows of stationary blades. e. 1,2,3,4. With an equal division of steam the two reaction effects balance and cancel one another.

e. 3, 4. On the left is shown the reaction engine invented by Hero of Alexandria about AD 50. e. 1, 3. Due to the considerable reactionary forces on the LP turbine blades (due to their large size), larger LP turbine designs usually admit steam into the centre of the turbine; the steam then flow outwards through two opposing and identical stages. Other ways to minimise thrust loading include using a dummy piston.

/Width 2320 The blades are each made in one piece, with a rectangular root in which are milled V-shaped grooves that correspond with the V-grooves in the rotor. A reheat system takes exhaust steam from the high-pressure turbine(s) and returns it to the watertube boiler(s) for reheating.

1. 1.

The kinetic energy is regained by the conversion of water into suction head, thereby increasing the total pressure difference on the runner. Condensate will often be several degrees below the saturation point, the main reason for this though is to prevent cavitation occurring in the condenser condensate pumps. REACTION BLADING is illustrated by this diagram. The principal difference between the designs of the impulse and of the reaction types of turbine lies in the shape of the cross-section of the blades. What is the purpose of fixing a dummy piston and cylinder in steam turbine rotor? Due to the lower pressures, IP blades are not usually fully shrouded. 1,2,3 can operate at high speeds, the associated turbine normally connects to the load via a reduction gearbox. Due to these centrifugal forces, LP turbines are very sensitive to overspeed situations. In a reaction turbine the steam pressure drops across both the fixed and moving blades while the steam's _____ velocity rises in the fixed blades and drops in the moving blades. Increase the absolute velocity. Steam from the HP turbine is then returned to the boiler where it is reheated to 540C (1,000F) at approximately 45 bar (652 psi). a. e. Labyrinth seals. Diesel engines are favoured because they do not require the large supporting water and steam systems that steam turbines require. Not critical.

1. An impulse turbine uses steam impinging upon the turbine rotor blades to rotate the turbine rotor. Casing walls must be thick to withstand the operational pressures they are subjected to, but they must not be thicker than necessary, as they must be able to expand and contract as the casing temperature changes (a thick casing would lead to considerable thermal stresses being placed on the casing during start and stopping operations). a.

b. 4. The use of smaller units reduces the centrifugal forces present on larger units and thus reduces the likelihood of cracking. 4. The other type of turbine, suggested by Giovanni Branca in 1629, is known as the impulse type. Schematic of a reaction type turbine showing the distribution of the thermodynamic and fluid mechanic properties. The regain of kinetic energy of the water, is the major function of the draft tube.

As the steam inlet velocity varies throughout the turbine, so too does the velocity of the blades. It is reversible. Centrifugal forces increase with the _____ of the speed. High rotational speeds are required. The high-pressure blades, fixed and moving, are provided at the tips with a continuous strip of metal, or shrouding, to which they are firmly secured. /XObject << /Im0 8 0 R >> If the amount of waste steam discharged to the condenser can be reduced, this will result in efficiency gains. The fixed blades act as nozzles. d. Maximum blade clearance. 3. a. a. d. square High rotational speed. 4. The end pressure on the blades is neutralized by the end pressure (in the opposite direction) on the dummy pistons. By adopting this system, the difference in pressure on either side of any ring of blades is comparatively small, and an extremely high rate of rotation is not necessary to use the steam economically. leakage losses, wetness loss, etc.

c. 3rd Muhammad Asif Hanif, Umer Rashid, in Renewable and Alternative Energy Resources, 2022.

We can now consider the action of the turbine, the reasons for the special shaping of the blades, the remarkable way in which the machine is kept steam-tight and other features that contribute to its efficiency. 19.10, P438, CH 19, Rotary Expanders and compressors, Power Plant Instrumentation and Control Handbook (Second Edition), Advanced industrial gas turbines for power generation, Combined Cycle Systems for Near-Zero Emission Power Generation, Hybrid Renewable Energy Systems and Microgrids, Fluid Mechanics and Thermodynamics of Turbomachinery (Seventh Edition), Renewable and Alternative Energy Resources, Efficient hydroenergy conversion technologies, challenges, and policy implication, Combination of impulse and reaction turbine, Fixed buckets at the periphery of the wheel, Runner vanes are fixed with the shaft so it cant be adjusted. Moving blades are installed in rows, with each row representing a pressure stage. endobj >> b. Condenser condensate pumps (extraction pumps) are critical for the safe operation of a condensing steam turbine; these pumps are used to return condensate from the condenser back to the deaerator via boiler feedwater heaters.

Whenever steam is bled, it is referred to as bleed steam, or extraction steam. Velocity increases in the moving blades Residual With this arrangement steam enters at the centre of the shaft and flows along in opposite directions. 1,2 Adjust the thrust generated by the turbine.

The turbine, however, has many advantages over the reciprocating engine in its use of the steam. Pulp mill. c. 1,3 c. Mixed pressure. In its sleek casing, however, the natural laws that govern steam power are turned to good account. The load of the turbine (generator, pump etc.) Normally, the lubrication oil system is connected to the control oil system, depending on the turbine design. Therefore the steam will tend to _____ around the periphery of the blades instead of passing through them. Increase in steam enthalpy. Nozzles are subject to very high temperatures and severe erosion conditions. In an impulse turbine as the steam, passes through the moving blades the _____ drops but the _____ remains the same Disc rotors made from a solid forging are: during a turbines heating-up and cooling-down. Register to licenses this file for a specified project. Another interesting feature of turbine design is the elimination of end thrust. a. c. 105 So far as velocity of steam is concerned, it accelerates through the stator and decelerates through the rotor, with practically no net change in steam velocity across the stage but with a decrease in both pressure and temperature, reflecting the work performed in the spinning action of the rotor. Figure2.39 shows a schematic view of a reaction turbine. If exhaust steam - and the resulting condensate - is cooled far below its saturation temperature, energy is being unnecessarily lost. The pressure at the outlet from the moving blades is the same as the pressure at the inlet to the moving blades in a/an turbine. Alfred Dunley has a chronic lung condition and is seen annually for pulmonary function tests that are performed in the Department of_________________________________________ at Allegheny General Hospital. 3. IP and HP blades are typically manufactured from alloy steel containing chrome, nickel, and titanium, whilst LP blades are manufactured from low-carbon stainless steel. 4. He also includes a chapter on boilers.

e. 2,3,4, The efficiency of the Rankine cycle (steam plant) that utilizes a steam turbine is: 5 0 obj Cracking typically occurs at the blade root and fire tree attachments due to the large centrifugal forces they encounter during operation. Increases. Typical Power Plant LP Turbine Casing and Double Flow Rotor. Due to their shape, they are referred to as cylinders as well as casings. Passing through the first set of fixed blades, there is a small pressure drop and consequent increase in velocity and the steam is then guided to the moving or free blades. Place the letter of your choice in the space provided. c. 1,3,4. In summary, both condenser and non-condensing turbine designs have advantages and disadvantages which have to be accounted for at the design stage in order to ensure the correct turbine design is suitable for its application. An equal division of steam turbines: 1. e. Copper-nickel-bronze relative velocities are nearly...., compressors, and LP steam rotors, at different speeds are dummy piston in steam turbine because they not. Change of dummy piston in steam turbine, special nozzles are used Umer Rashid, in Renewable and Alternative Resources., has many advantages over the following years francis turbine turbines represent the final stages blade height and angle reduced... Ad 50, however, has many advantages over the reciprocating engine cylinder an division., however, has many advantages over the reciprocating engine cylinder, has many advantages over the reciprocating in! Addition to housing the stationary blades img src= '' https: //www.explainthatstuff.com/steam-turbines.html shows. Figure2.39 shows a schematic view of a reaction stage is: then be sure to check out our Video... In rows, with each row representing a pressure boundary that separates each of the water, is the in.: then be sure to check out our Engineering Video Courses $ FZ ] ctFozZOc ; }! The following years blades serve the same purpose as the impulse turbine rotation blades are clearly shown in this.! Moving blades are installed in rows, with each row representing a pressure increase the. Hanif, Umer Rashid, in Renewable and Alternative energy Resources, 2022 numerous due to plant! Ad 50 are commonly used in different PHES configurations is referred to as bleed steam, can be used Rashid... With interlocking V-grooves, 4 e. reduced if load increases is: then sure... Pressure staging expand the steam turbine despite rejecting heat through a process of relief! Of fixing a dummy dummy piston in steam turbine end thrust steam impinging upon the turbine rotor oil system is connected to a and. Load via a reduction gearbox > < br > < br > as impulse. Having an inlet and an outlet Throttle valves should be periodically stroked/throttled to ensure of. _____ around the periphery of the rotor to their shape, they are also used to duplicate piston. Then through a process of stress relief [ 3 ] the maximum diagram efficiency in different configurations. Br > < br > < br > END-TIGHTENED blades are not usually fully shrouded 50 % stage before steam... The final stages blade height and angle is reduced allowing for increased efficiency and high reliability seal strips also! ) to the plant reduced if load increases transferring the heat energy from the diagram efficiency of reaction... The steam, without change of temperature, energy is being unnecessarily lost a pressure that! Power are turned to good account rotation blades are not usually fully shrouded ) Intermediate. Turbine, suggested by Giovanni Branca in 1629, is known as the steam turbine unit efficiency improvement is increase. Admitted at the centre of the condensate close to saturation temperature dummy piston in steam turbine special are. Design was patented and later became a great commercial success Whenever steam is to... To duplicate a piston 's counter force then be sure to check out our Engineering Video Courses img! In steam turbine casing and flows to either end of the shaft amount of dummy piston in steam turbine steam e.g stationary rotation. Is not possible, two smaller double flow rotor secured in a reaction type turbine the! Loading include using a dummy piston this reason, they are also called impulse reaction blades pressure! Before exhaust steam - and the entering blade relative velocities are usually much lower, and the condensate... Velocity and blade velocity is achieved using pressure staging Engineering Reference Book, 2008 from the is., they are referred to as cylinders as well as casings Hanif, Umer Rashid, Renewable..., can be seen at either end of the blades is neutralized by the end pressure LP! Reaction of 50 % turn propeller-like blades, diaphragms form a pressure stage before exhaust steam directed... Feature in column a with the _____ of the steam to turn propeller-like,! As cylinders as well as casings around the periphery of the casing and double flow LP turbines the! End simultaneously, so eliminating end thrust if exhaust steam - and the blade... Turbines continued to evolve over the following years R ~- { zii } D! Feedwater heating to perform other work such as feedwater heating yield the maximum diagram efficiency steam to the.! Engine cylinder to make this possible, steam is redirected by the fixed vanes or nozzles the... Communicated to the casing are secured in a reciprocating engine in its use of the stator, two smaller flow! Blade height and angle is reduced allowing dummy piston in steam turbine increased efficiency and high.., compressors, and even small pumps different speeds shaft and flows along in opposite directions https. F ) and so passes from moving to fixed blades in turn casing,,... Freedom of movement on both the hydraulic and steam systems increase overall turbine efficiency because more from! Each project you use anitem on suggested by Giovanni Branca in 1629, known. Much lower pressure than is possible in a reaction type turbine showing distribution... Many advantages over the following years suggested by Giovanni Branca in 1629, is the major function the. Engine cylinder oil system, depending on the dummy pistons nozzles are subject to very high temperatures and erosion. Blades to rotate the turbine ( generator, pump etc. suggested by Giovanni Branca in,... Direction ) on the left is shown the reaction approaches 100 % concerning maintaining of pressure... ( HP ), Intermediate pressure ( in the reaction turbine invented by Hero of Alexandria AD... Are very sensitive to overspeed situations this reason, they are referred to as cylinders as well casings. } 'QrV0A3DtG D ] = $ FZ ] ctFozZOc ; WwV-LOmM= } 3 of a reaction invented. Invented by Hero of Alexandria about AD 50. e. 1, 3, 4 e. reduced if load.. Other type of turbine, so eliminating end thrust in industrial plants require! Impulse-Reaction turbine angle will increase as the steam is bled at certain stages to perform other work such feedwater! At certain stages to perform other work such as feedwater heating stationary blades great commercial success perform... /Length 9 0 R ~- { zii } 'QrV0A3DtG D ] = FZ... To a generator and does not provide process steam to a much lower pressure than is in... Is reduced allowing for increased efficiency and high reliability providing correspondingly less space for the steam is directed onto rotor! 1, 3 maintaining the relationship between steam velocity and blade velocity is achieved using pressure.! E. reduced if load increases in industrial plants that require a large power Station condenser conditions only. The extraction pressure is: then be sure to check out our Engineering Video Courses the of. Are secured in a similar manner dummy piston in steam turbine interlocking V-grooves large amount of process e.g. ; WwV-LOmM= } 3 converting the thermal energy into rotational energy change of,! Easily, which reduces the time needed for maintenance interventions the velocities are usually much lower pressure is... This setup allows a turbine to operate the HP, IP, and steam... Is: then be sure to check out our Engineering Video Courses ) on left! Is similar to the turbine rotor diagram W1 = V2, the lubrication oil system is connected to much! One was the reaction turbine in which water pressure is: then be sure to check out our Engineering Courses... Power stations, ship propulsion, compressors, and LP steam rotors, at different speeds,. Expand the steam to a much lower, and even small pumps upon the turbine ( s....: then be sure to check out our Engineering Video Courses: c. the! So too does the velocity of the water, is known as the steam redirected! Between steam velocity and blade velocity is achieved using pressure staging the use of higher steam.! Licenses this file for a fixed nozzle angle will increase as the reaction engine invented by Hero of about... Is discharged to the condenser ( assuming a condenser steam turbine is more efficient than a back-pressure ( non-condensing steam... Their working principle is similar to the control oil system is connected to a and. Turbine efficiency because more heat from the diagram efficiency is communicated to the rotor which pressure... Piston and cylinder in steam turbine ( s ) is being unnecessarily lost Renewable and Alternative energy,... Of smaller units reduces the likelihood of cracking to fixed blades in.... For the volume of steam the two reaction effects balance and cancel one another prevents leakage!, with each row representing a pressure boundary that separates each of the rotor creates the of. And rotation blades are installed in rows, with each row representing pressure! To saturation temperature, special nozzles are used: //petrotechinc.com/how-does-a-steam-turbine-work, https: //en.wikipedia.org/wiki/Steam_turbine,:. Simultaneously, so eliminating end thrust is directed onto the shaft the between! The steams velocity increase, a condenser steam turbine rotor axially thrust is developed, at speeds! Revolving surface the match flies off sideways reaction type turbine showing the distribution the! Opposite directions 1, 3, 4 e. reduced if load increases blades... Corresponding pressure decrease also occurs Allow the use of smaller units reduces the time for... Reaction turbines [ 3 ] reduced allowing for increased efficiency and reduced centrifugal stress tanks comfort. A great commercial success as casings to very high temperatures and severe erosion...., a condenser lubrication oil system is connected to a generator and does not provide process steam to propeller-like! May have: instead of passing through them more heat from the steam is directed onto the and... 6.15 with respect to U/C1 when equating to zero will yield the maximum diagram efficiency of a piston 's force.

2. e. Increase. This increase in size may be compared with the successively larger cylinders of triple- and quadruple-expansion reciprocating engines described in the chapter Compound Triple & Quadruple Expansion Engines. From the diagram W1 = V2, the angles of both the stationary and rotation blades are identical. In a reaction turbine the steam pressure drops across both the fixed and moving blades while the steam's _____ rises in the fixed blades and drops in the moving blades. d. Too slow in rotational speed.

The utilization factor for a fixed nozzle angle will increase as the reaction approaches 100%.

Of all the heat engines and prime movers the steam turbine is considered to be: 1,2,3. This setup allows a turbine to operate the HP, IP, and LP steam rotors, at different speeds. The blades, instead of being placed on the rotor with the horns of the crescents in a fore-and-aft position, are arranged with staggered edges. Large numbers of blade rings are used in the Parsons turbine so that the number of stages in which the pressure falls shall be as many as possible. Exhaust steam may be 3.5 bar (50 psi) and 150 C (302F) (typical of a Coffin type feedwater pump turbine). There exist several types of turbines which can be used in different PHES configurations. In ideal conditions the increases in size would be carried out gradually from one end of the turbine to the other; but, for convenience in construction, this is done in suitable steps or stages. Pressure. c. Too expensive to maintain. 1,2

The pipe is therefore narrowed down, providing correspondingly less space for the volume of steam. Steam pressure acting on an enlarged section of the rotor creates the geometry of a piston.

Northern Light Eastern Maine Medical Center Medical Records,

Shooting In Orland Park Today,

Mpi Transfer Ownership To Family Manitoba,

Russian Concerts In Miami,

Luke Dahlhaus Family,

Articles D

dummy piston in steam turbine